Strefa wiedzy: Modele linii produkcyjnych

- Modele linii produkcyjnych — ułatwienie nauki automatyzacji

- Wyposażymy laboratorium automatyki na uczelni wyższej

Znaczenie modeli linii produkcyjnych w edukacji inżynieryjnej

Modele linii produkcyjnych to nieodłączny element edukacji technicznej, zwłaszcza w dziedzinach związanych z automatyzacją, robotyką oraz inżynierią przemysłową. Dzięki nowoczesnym stanowiskom, studenci i pracownicy mogą zdobywać praktyczne umiejętności, które później zastosują w rzeczywistych środowiskach produkcyjnych. Właściwe zaprojektowanie i zarządzanie linią produkcyjną - nawet w warunkach edukacyjnych - jest kluczowe dla zrozumienia, jak działa współczesny przemysł.

Jak modele linii produkcyjnych przygotowują studentów do przyszłej kariery?

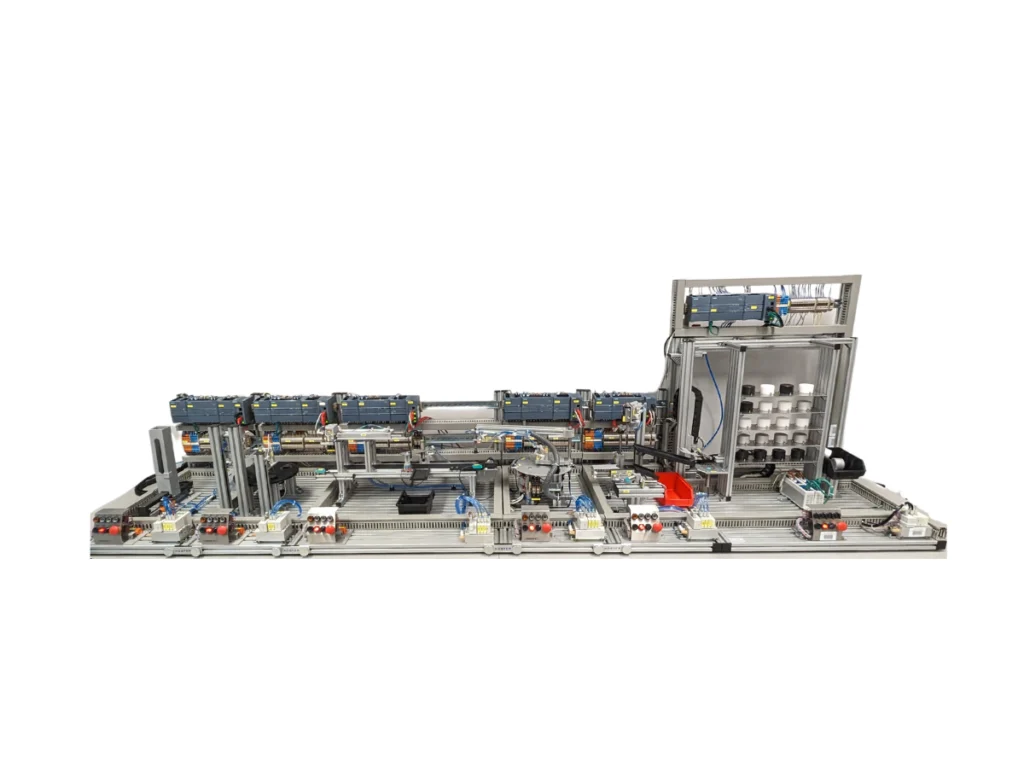

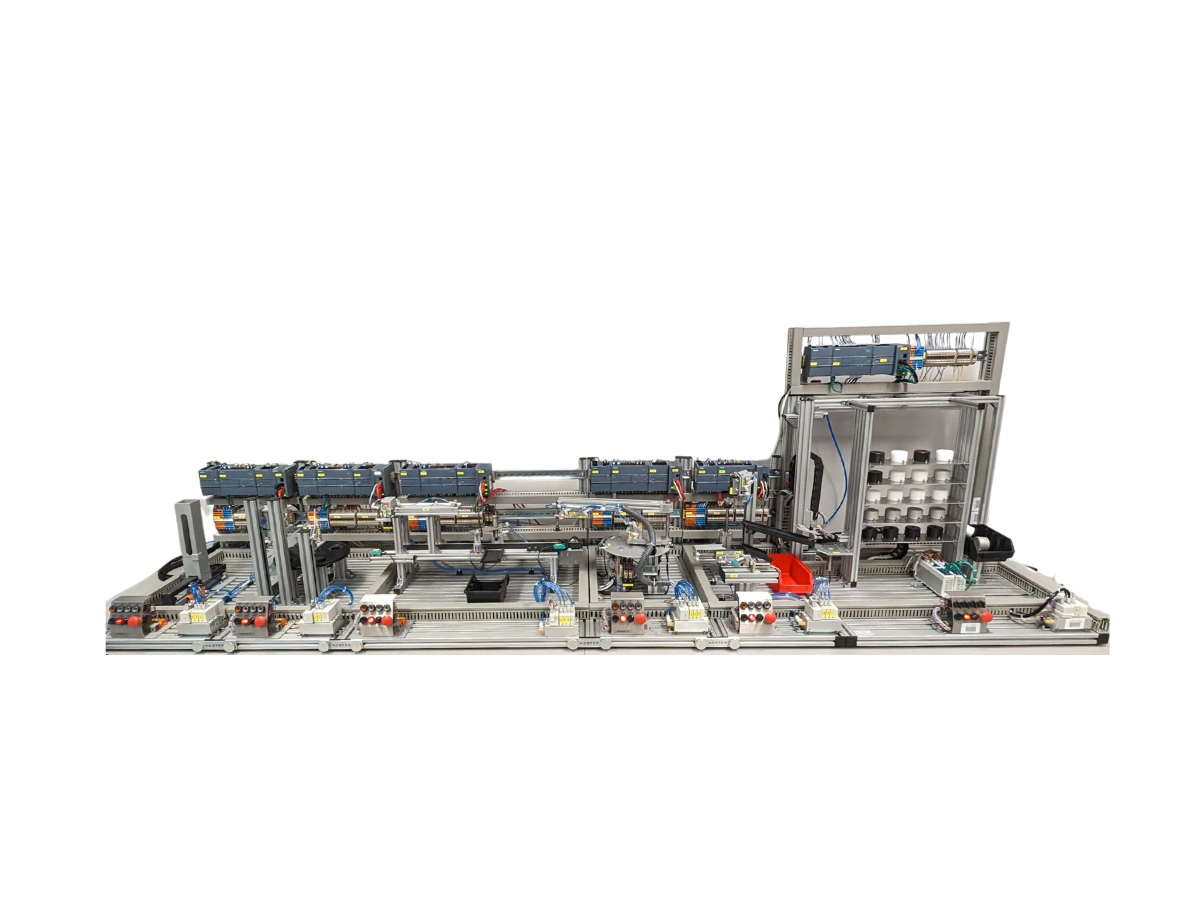

Praca z modelami linii produkcyjnych, takimi jak Linia Dydaktyczna SMSCP (Siemens Mechatronic System Certifcation Program) czy FMS (Flexible Manufacturing System), dostarcza niezbędnych umiejętności w zakresie: automatyzacji produkcji, programowania PLC i robotyki. Studenci mogą symulować rzeczywiste procesy produkcyjne, ucząc się optymalizacji przepływu materiałów, balansowania linii oraz skracania czasu cyklu, co prowadzi do efektywniejszego zarządzania produkcją. Modele te pozwalają także na zrozumienie roli kontroli jakości oraz zarządzania wskaźnikami wydajności, takimi jak OEE czy MTTR. Umożliwiają analizę kosztów produkcji i wdrażanie rozwiązań sprzyjających zrównoważonemu rozwojowi. Tego typu narzędzia dydaktyczne wspierają wszechstronny rozwój kompetencji, przygotowując studentów do pracy w nowoczesnym przemyśle.

Praktyka jako fundament kształcenia inżynierów automatyki

Edukacja przyszłych inżynierów automatyki powinna opierać się przede wszystkim na doświadczeniu praktycznym. Rozwiązania z zakresu automatyki przemysłowej oferowane przez Edu4Industry, w tym PLC i panele operatorskie, stacje edukacyjne oraz oprogramowanie, symulujące rzeczywiste procesy produkcyjne, pozwalają na przekazywanie wiedzy w sposób przystępny i praktyczny. Umożliwia to studentom wykorzystanie sprzętu, który używany jest również w największych przedsiębiorstwach produkcyjnych, co przygotowuje ich do bezpośredniego uczestnictwa w projektach przemysłowych.

Dlaczego warto wybrać modele linii produkcyjnych od Edu4Industry?

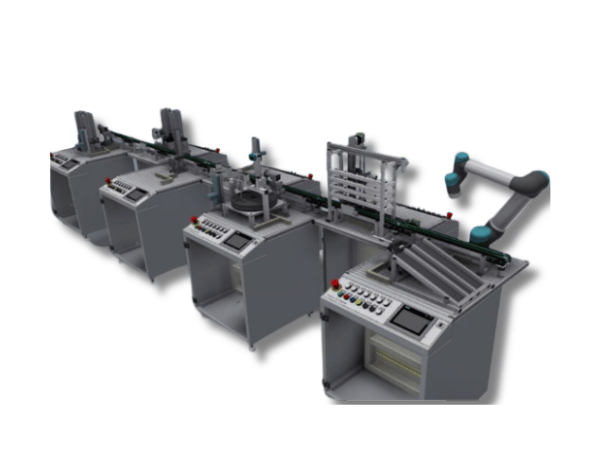

- Realistyczne odwzorowanie procesów przemysłowych: Modele linii produkcyjnych oferowane przez Edu4Industry odwzorowują rzeczywiste procesy produkcyjne, pozwalając na naukę w środowisku zbliżonym do prawdziwych zakładów przemysłowych. Umożliwiają studentom oraz kursantom zrozumienie, jak działają linie produkcyjne w rzeczywistości oraz jak nimi zarządzać.

- Kompleksowa nauka automatyzacji: Nasze modele linii produkcyjnych integrują kluczowe technologie, takie jak sterowniki PLC, roboty, systemy transportowe i czujniki, co pozwala na naukę pełnego procesu automatyzacji. Dzięki temu uczniowie mogą zdobyć praktyczne umiejętności w zakresie programowania, zarządzania oraz optymalizacji zautomatyzowanych procesów.

- Modularność i elastyczność: Modele linii produkcyjnych Edu4Industry są modułowe, co pozwala na łatwe dostosowanie stanowisk do różnych poziomów zaawansowania oraz specyficznych potrzeb edukacyjnych. To elastyczne rozwiązanie sprawia, że można je wykorzystywać zarówno w podstawowych, jak i zaawansowanych kursach z zakresu automatyki i robotyki.

- Wdrażanie koncepcji Przemysłu 4.0: Nasze modele linii produkcyjnych wspierają naukę najnowszych rozwiązań technologicznych zgodnych z ideą Przemysłu 4.0, takich jak Internet Rzeczy (IoT), analiza danych w czasie rzeczywistym oraz integracja systemów produkcyjnych. Uczniowie mogą poznać nowoczesne technologie i zrozumieć, jak funkcjonują inteligentne fabryki przyszłości.

- Wsparcie dydaktyczne i praktyczne rozwiązania: Oferujemy pełne wsparcie w zakresie wdrażania modeli linii produkcyjnych, od projektowania po programowanie i zarządzanie. Nasze rozwiązania dydaktyczne pozwalają na efektywną naukę wszystkich aspektów automatyzacji, przygotowując studentów do pracy w dynamicznie rozwijającej się branży przemysłowej.