Universal Board Process Simulator

Universal Board Process Simulator

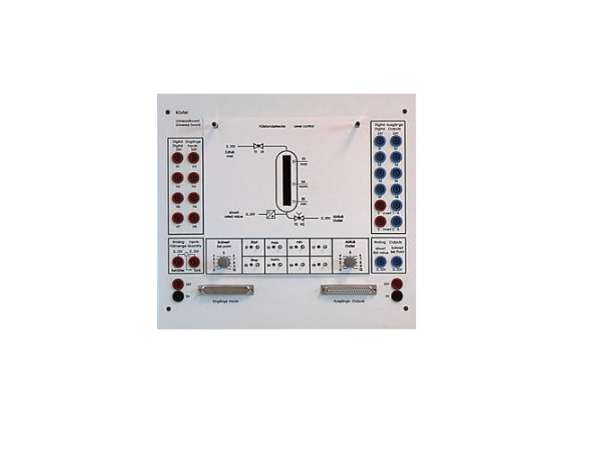

The Universal Board allows simulating various processes in the field of electricity, drives, machine control, processes and more. By performing exercises students may address various challenges typical to industrial automation. The kit comes with 24 add-on cards that illustrate various scenarios.

INQUIRY

How it works:

The simulator allows students to learn the basics of controlling a wide range of industrial installations. The board is equipped with a LED matrix. After applying the selected card, the user can see the process diagram, the appropriate LED diodes and a 10-segment light bar (for level visualization). Digital inputs and outputs are connected in parallel with sockets and 37-pin system connectors.

Types of exercises on 24 templates:

- Star-delta motor control

- Polarity switch

- Resistance starts

- Swing motion control

- Cleaning station

- Bender

- Drilling station

- Bender (2)

- Gate control

- Lock control

- Door control

- Conveyor

- Sorting line

- Installation inspection

- Tank’s filling installation

- Pump control 1

- Pump control 2

- Reactor filling machine

- Buffer tank

- Filling the tank

- Compressed air installation

- Mixing station

The board includes:

- 8 digital inputs 24V, 8 digital outputs 24V

- 2 inverters

- 2 analog inputs with 0-10V adder

- 2 analog outputs 0-10V, power supply via 24 V / 0.3A system connector

- 4mm safe electrical socket, 37 pin SUB-D for system connectors

Control

Models are controlled by setting and reading digital input and output signals from a PLC connected via DB37 connectors. Additionally, the set is equipped with a control panel with 8 switches. Inverters simulate NC contacts. Potentiometers are used to set and adjust the setpoints and disturbances. Signals from analog inputs are fed to the adder.