Inspection Robots: Enhancing Efficiency and Safety Across Industries

The energy sector, manufacturing, warehousing, and construction site monitoring—these are just a few of the industries where inspection robots play a crucial role. Designed to navigate hard-to-reach and hazardous environments, these robots mitigate risks that would otherwise endanger human workers. They also excel at automating repetitive tasks, improving efficiency and consistency.

From legged robots and drones to wheeled and tracked platforms—what exactly are inspection robots, and where do they deliver the most value? Let’s take a closer look.

What are inspection robots?

Inspection robots are advanced technological systems equipped with autonomous or remote-controlled capabilities. Their primary function is to monitor and assess the condition of critical infrastructure, machinery, and industrial environments. By leveraging high-precision sensors, cameras, and artificial intelligence, these robots enhance inspection processes that would otherwise be dangerous, time-consuming, or inefficient if performed by humans.

Key applications of inspection robots

Thanks to their adaptability and cutting-edge technology, inspection robots are deployed in various industries, including:

1. Manufacturing facilities and construction sites

Inspection robots perform repetitive monitoring tasks, such as evaluating machinery performance and ensuring safety compliance in production plants and construction sites. Outfitted with high-resolution cameras, LiDAR, and thermal sensors, they detect structural flaws, document project progress, and flag anomalies for human operators. This improves real-time oversight while enhancing worker safety and operational efficiency.

2. Hard-to-reach environments

Drones play a pivotal role in inspecting areas that would otherwise require costly and time-intensive solutions like scaffolding or industrial rope access. These aerial robots conduct rapid, precise inspections of power lines, wind turbines, and large-scale structures. With advanced imaging and sensing technologies, they provide high-quality visual data, enabling engineers to assess asset conditions and detect early signs of wear or failure. This translates to improved maintenance strategies and cost savings.

3. Hazardous work zones

In chemical plants and refineries, inspection robots monitor temperature fluctuations and detect gas leaks without exposing personnel to danger. They are widely used in industrial warehouses storing flammable substances, ensuring compliance with safety regulations.

By leveraging cutting-edge technologies such as cameras, LiDAR, advanced sensors, and artificial intelligence, inspection robots can autonomously collect data and conduct analyses without human intervention.

Advantages of inspection robots

Despite variations in mobility, control systems, and autonomy levels, inspection robots share several core benefits:

Resilience in extreme conditions (e.g., high temperatures, radiation, underwater environments)

Access to confined or hazardous areas

Continuous operation with minimal human intervention

Reduction in manual labor and industrial downtime

Key features of inspection robots

The selection of inspection robots depends on several key factors, including the operating environment, control method, and required sensors.

Key considerations include:

Control method |

|

Inspection technologies |

|

Mobility & design |

|

Industry-specific use cases

1. Industrial manufacturing

Autonomous inspection robots streamline data collection, quality control, and production line monitoring. By automating inspections, manufacturers can enhance productivity and accuracy while reducing human error.

2. Pipeline inspection

Pipeline infrastructure requires routine assessments to identify damage, corrosion, or leaks. Equipped with advanced sensors and navigation systems, inspection robots provide real-time diagnostics, ensuring proactive maintenance and minimizing costly disruptions.

3. Energy sector

From nuclear and conventional power plants to wind and solar farms, inspection robots conduct comprehensive evaluations of turbines, transformers, and transmission lines. AI-powered image recognition enables them to autonomously detect faults, log anomalies, and trigger maintenance alerts—enhancing asset reliability and longevity.

4. Construction site & inspection robots

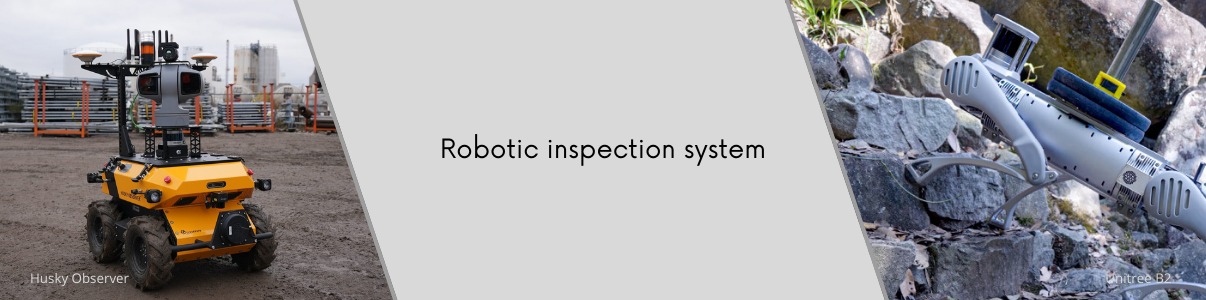

Inspection robots are also used for construction site monitoring and tracking project progress in remote locations. A great example is the Husky Observer—a rugged, all-terrain robot designed to navigate steep obstacles and muddy surfaces with ease. Additionally, its 100 kg payload capacity allows for the integration of various sensors or even a small manipulator, making it a highly versatile solution for construction site automation.

5. Search & rescue operations

In disaster-stricken zones—earthquakes, floods, or building collapses—inspection robots support emergency teams by navigating through debris and transmitting critical real-time data. Their ability to operate in smoke-filled, dusty, or unstable environments makes them indispensable in life-saving missions. Quadruped robots excel in these scenarios due to their superior agility and stair-climbing capabilities.

6. Environmental & ecological research

Autonomous mobile robots are increasingly deployed for environmental monitoring, tracking air, water, and soil quality. These systems help detect toxic leaks, assess climate change effects, and support natural disaster mitigation efforts.

7. Agriculture

Inspection robots are revolutionizing precision farming by monitoring crop health, soil conditions, and irrigation levels. Key applications include:

Identifying plant diseases and pests

Analyzing soil moisture and nutrient levels

Optimizing harvest planning and yield predictions

8. Defense & military applications

Quadruped robotic systems are gaining traction in modern defense operations. Their mobility, autonomy, and rugged design make them ideal for reconnaissance, surveillance, and logistics support in complex battlefield environments.

The future of inspection robotics

Inspection robots are pushing the boundaries of what’s possible, operating in extreme environments—from high-temperature industrial zones and deep-sea explorations to outer space missions. By automating inspections, organizations can improve safety, enhance efficiency, and optimize resource allocation.

Looking for advanced inspection solutions?

We specialize in matching the right robotic systems to your unique needs.