Three-axis force/torque sensor in the end joint (ranges: ±150 N / ±10 Nm)

UR15

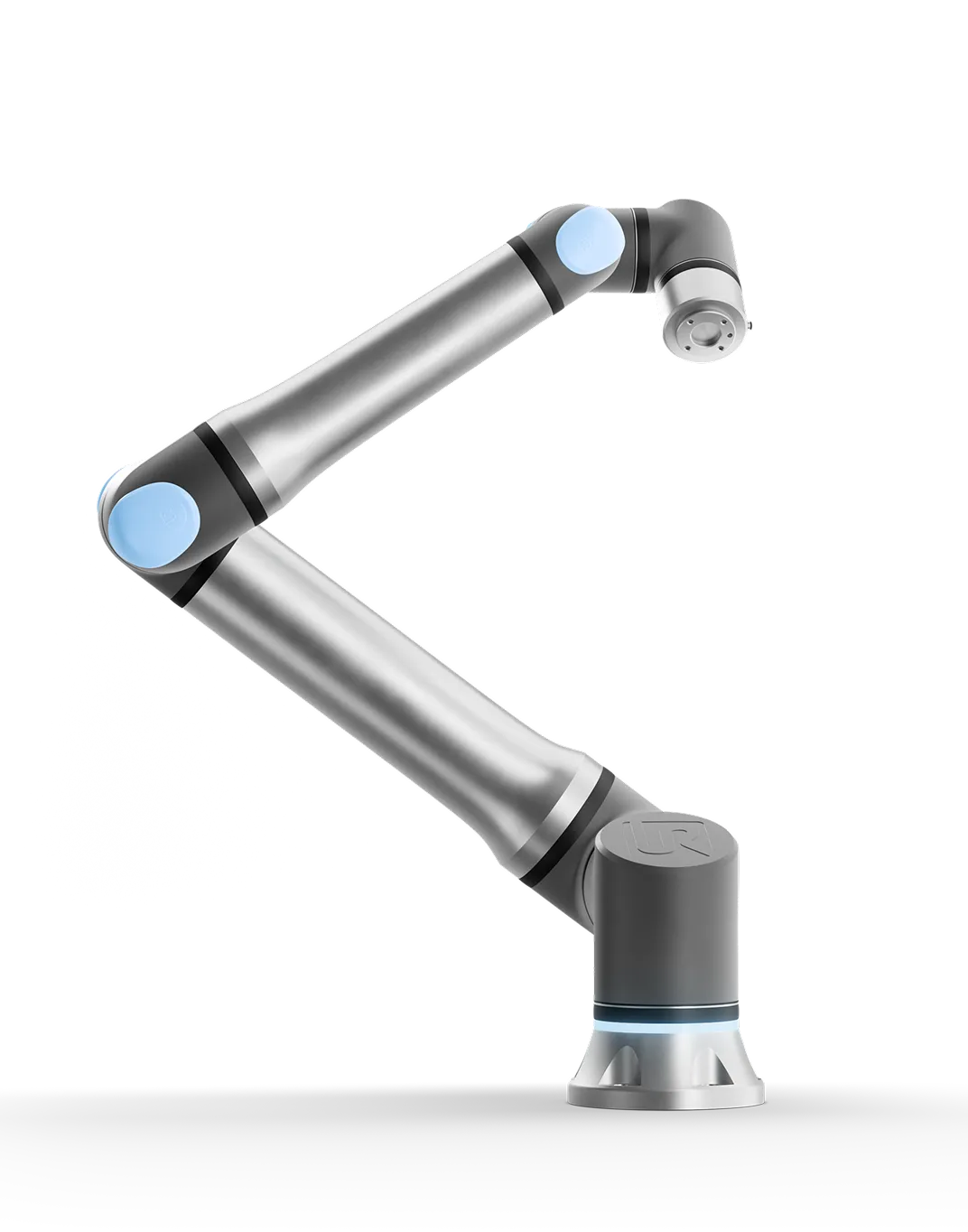

Collaborative Robot UR15

UR15 is a six-axis collaborative robot with a payload of 17.5 kg and a reach of 1300 mm, designed for fast and precise operations in space-constrained environments. It features a compact design, high operating speed (up to 5 m/s), and easy integration with industrial automation systems as well as educational and research setups.

In academic and research applications, the UR15 serves as a flexible platform for experiments in motion control, human–robot interaction (HRI), trajectory programming, and sensor and vision system integration. Its open communication architecture and support for common industrial protocols (PROFINET, Ethernet/IP, Modbus TCP) enable seamless connection with laboratory systems and teaching workstations.

INQUIRY

Your data is the data that allows us to make the first business contact. All data provided in the form are treated as confidential. Personal data appearing in the form will be processed in accordance with our privacy policy, available at www.edu4industry.com.

Parameter | UR15 |

Position repeatability | ±0.05 mm |

Lifting capacity (without gripper)17 | 17 kg |

Range | 1300 mm |

Degrees of freedom | 6 |

Protection level | IP65 |

Ports on the controller | 2x DI, 2x DO, 2x AI, 2x AO |

Communication interfaces | Profinet, Ethernet/IP, Modbus TCP, USB 2.0/3.0 |

Force / torque sensor |

The UR15 combines high motion dynamics with excellent positioning repeatability, making it well suited for tasks such as machine tending, palletizing, welding, assembly, and quality inspection. Thanks to its compact footprint (base diameter 204 mm, weight 40.7 kg), it can be easily deployed in existing production lines, including those with limited workspace.

The OptiMove motion control technology allows smooth adjustment of speed and acceleration, minimizing vibrations and reducing cycle time. The PolyScope software provides intuitive configuration and integration with higher-level control systems (SCADA, PLC).

The UR15 offers six degrees of freedom, enabling execution of complex 3D motion trajectories. Its IP54-rated construction and TÜV and UL 1740 certifications ensure safe operation in industrial environments. The robot is equipped with a three-axis force/torque sensor in the end joint, enabling contact control with the environment and precise tool guidance.